TS 410 Petrol Cut-off Machine

R 18,863.00

All prices include 15% VAT.

Select item

Available to buy from STIHL Approved Dealers

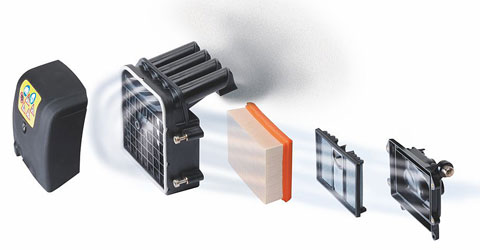

TS 410 petrol cut-off machine: compact, robust and powerful

The TS 410 is a lean, clean, cut-off machine that’s easy to use and easier to maintain. Just squeeze the trigger and watch its 12” cutting wheel grind through iron, steel, concrete and expectations. This model features advanced filter technology that automatically handles daily maintenance. Its revolutionary X2 air filtration removes 99.96% of particles from air entering the carburetor and engine, making its onboard filters virtually maintenance free. Good thing we included an anti-vibration system to maximize comfort – a feature you’ll appreciate after a full day of cutting.

Equipment and function

The pictures shown are sample photos. The actual appearance of the equipment features and their specific attachment to the product may differ from the pictorial representations, but will have the same functionality.

Technical details

| Capacity | 66,7 cm3 |

| Weight | 9,5 kg 1) |

| Performance | 3,2 kW |

| Tank volume | 0,71 l |

| Mains water supply | Standard 1/2" |